"The robots are not only very smart, but also sustainably deployable"

LIOF helps this entrepreneur with:

LIOF helps this entrepreneur with:

Robomotive contacted LIOF and received a subsidy from the LimburgMakers project to further develop the robot cell. Michael Vermeer of Robomotive: "The subsidy from LIOF enabled us to make a 'skid' version of our robot cell: our first mobile demo robot cell!"

Ruud Nissen, business developer at LIOF: "With the robots, Robomotive contributes to the smarter organization of the logistics process. The robot also offers an ergonomic advantage: it can lift more than 25 kilos. In this way, the robot not only takes repetitive work off your hands, but also (excessively) heavy work.

For enterprising and innovative Limburg Together with entrepreneurs and partners we are working towards a smarter, more sustainable and healthier Limburg by focusing on the transitions energy, circularity, health and digitization.

Innovative entrepreneurs are supported by LIOF with advice, network and financing.

LIOF and Robomotive

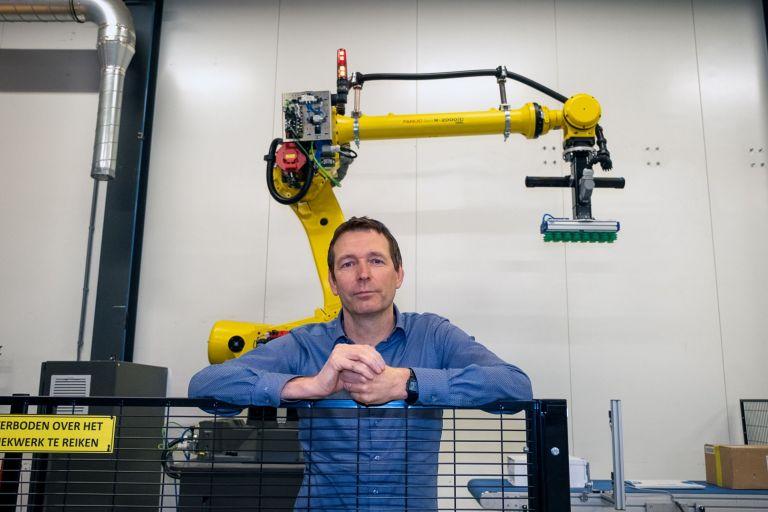

Michael Vermeer, CEO and Founder of Robomotive, explains.

"Humans have complex hand-eye coordination. Our robots can mimic this. This means that they can pick up all kinds of different types and sizes of products and put them down again somewhere else. We do this by giving our robot arms two important things: 3D vision: the camera 'eyes' that can see depth just like humans. And adaptive grippers: the robot's 'hands and fingers."

The robot doesn't have to learn anything. Michael passionately explains all that the robots are capable of. "The robots don't have to learn anything. They can pick up boxes, crates and, for example, bottles, tubes and cans from a crate or from a pallet, without the robot ever having grasped them before or been given any data about them."

He 'sees' what he needs to do "Also, the products may be random in a crate. Or have a stacking pattern on a pallet that is unknown to the robot. The robot 'sees' what it needs to do. As long as the size and weight are within the limits of the system. We make this possible with our smart software."

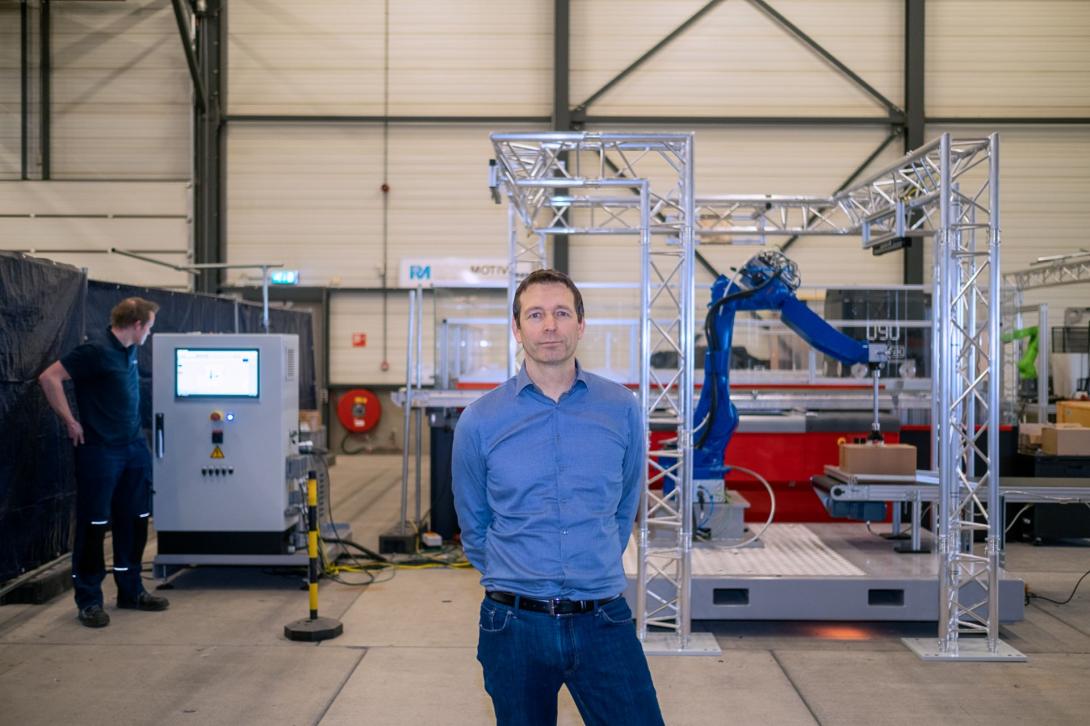

Nailed to the ground The next step for Robomotive was to make the robots more mobile. "A robot actually consists of a number of 'main components': the robot, the gripper, the camera and the control box," Michael explains. "In 2018, we delivered a robot cell to DHL in Beringe for picking boxes from pallets. But the control box was separate from the robot. In addition, the robot had to be bolted to the ground. That got us thinking."

That can be done differently! Robomotive contacted LIOF. And received a subsidy from the LimburgMakers project to further develop the robot cell. "With the subsidy from LIOF we were able to make a 'skid' version of our robot cell: our first mobile demo robot cell!"

With the mobile robot cell, the robot, gripper, camera and control box are all on one steel frame. Michael enthusiastically emphasizes the benefits: "With a forklift, the customer can easily take the robot cell to another location to perform another function. This allows customers such as DHL to use the robot cell for much longer and more multifunctional use, for multiple products, functions or customers. This makes our robots not only smart, but also more sustainable."

Make heavy work lighter When it comes to smart, sustainable and healthy initiatives, the feelers at LIOF are immediately on edge. It didn't take long for them to decide to support this innovative Limburg company. Ruud Nissen, business developer at LIOF: "With its robots, Robomotive contributes to the smarter organisation of the logistic process. The robot also offers an ergonomic advantage: it can lift more than 25 kilos. In this way, the robot not only takes repetitive work off your hands, but also (excessively) heavy work.

Michael faces the future with an open mind. And rightly so. "Our demo robot cell was nominated for the Logistica award in 2019. We have also now sold several mobile robot cells." Robomotive is now using its demo robot in Roermond to show customers first-hand how the robots work. "They can even bring their own products for this. After all, what could be better than seeing the benefits for your product 'live' in action?"

Leave the boring, heavy and dangerous work to robots. Finally, does Michael have a great tip for other entrepreneurs focused on smart, sustainable and innovative business? "Try to leave the boring, heavy and dangerous work to robots as much as possible. And use people for the creative, social and problem-solving tasks in a company. Because let's face it, we haven't developed robots for that yet ...!"