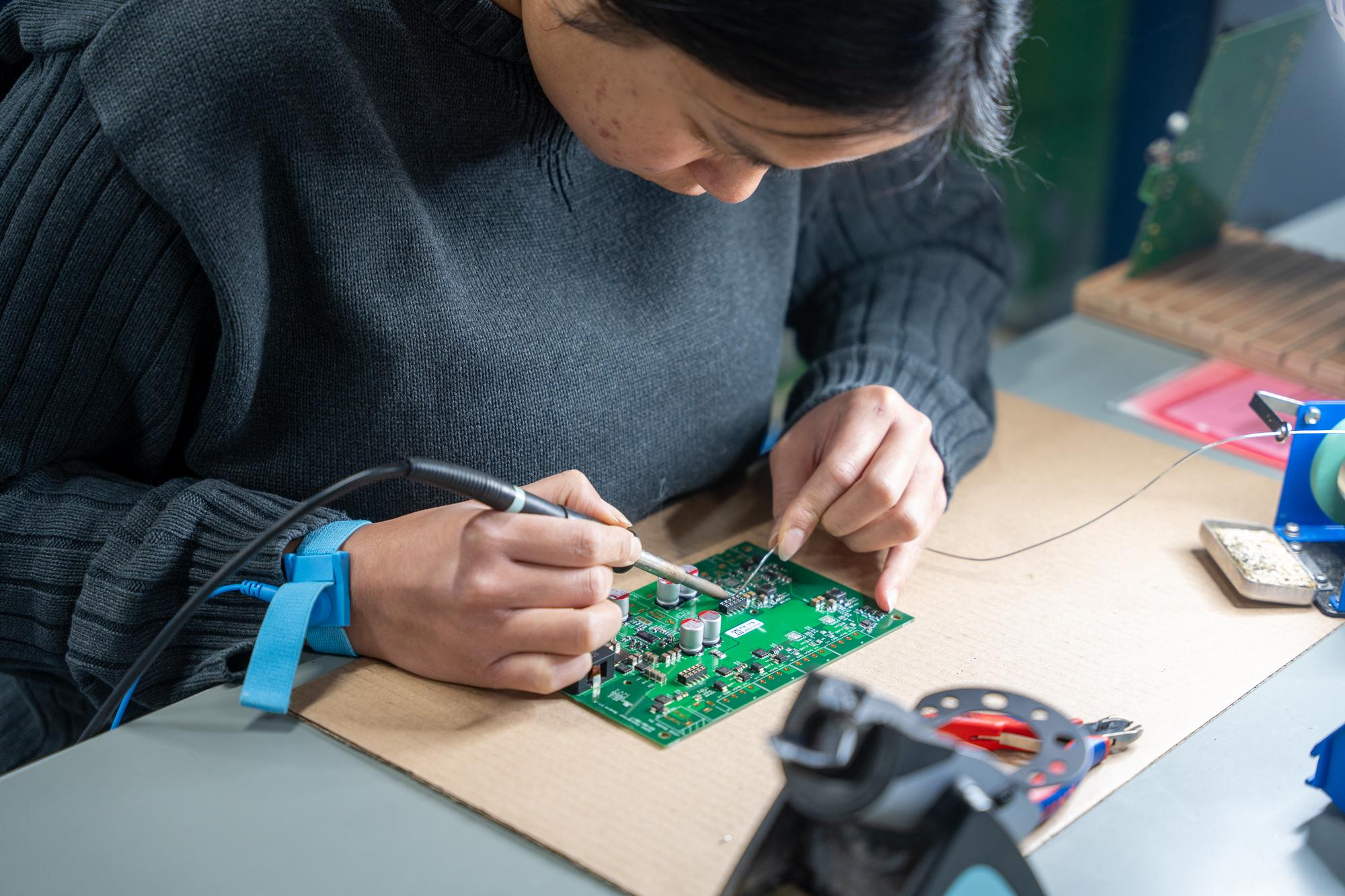

John Derikx, 58, has had quite a world tour. The techie by origin was a director of several large companies, at home and abroad. Since 2015, John has been founder and owner of DCPower4C in Kerkrade. The company produces battery systems for hospitals and the process industry.

The Kerkrade native, born and raised in the village of Eygelshoven, was eager to do business locally after a long time abroad. Against the current of people claiming that "not much happens here anyway," John decided to prove otherwise. With the largest customer in England, expansion into Switzerland and even Australia, his company is taking important first steps.

"Wherever there are challenges with mobile energy supply, our battery systems can provide the solution."

Custom solutions

Together with suppliers, DCPower4C can have a working prototype ready within 3 weeks. "We can switch very quickly with customers who want a custom solution quickly. Our battery system is completely modular. By rebuilding it each time, we can offer many more options than existing solutions. Plug-and-play, for example."

Eyeopener

As with many other companies, Covid was going through a difficult period. Scarce materials, long lead times. But it was also an eye-opener that got many of us thinking. "After all, why do we have to throw everything away if it's used?" A question John often asks himself. In any case, it's not circular. And he thinks that needs to change. "I also think about the future, about our children and the next generations. It's going to stop sometime," John said.

With circularity in mind, John decides to look for new opportunities. "Sometimes you have to take a different path; that's part of being an entrepreneur. We are now at a point where we know what we want and how we want it. The next step is the actual execution."

Product-as-a-Service (PaaS)

Instead of selling battery systems, DCPower4C is working toward a Product-as-a-Service (PaaS) model. Necessary to make the transition to circular, but also interesting as a revenue model and less sensitive to unstable economic situations. "We want to completely unburden the customer," says John. "It's more attractive cost-wise, they no longer have to worry about the batteries and we can reuse. We already have ideas about this, we're working on that."

Small steps forward

.It takes a lot of time and work to set this up. "We take it one step at a time and find the right people to go with it. It's not about what you can do all by yourself, but who you know. That's very important. And so you try to develop a new system step by step. Of course, we also look at examples and other companies."

"You start somewhere and on the go you have to keep learning. There are multiple facets that come into play."

Other Method

Choosing PaaS also creates a very different way of working and structure. "We are certainly aware of that. We are looking for partners who can help us. This is how we are trying to take more and more control of the circular process. Right now, we don't have any influence on the end station of our batteries. That step is now too big for us as a small player. But with this change, they come back to us after use."

Monitoring and optimization

Now parts are replaced preventively, but actually that is not necessary. "A battery has a lifespan of about 3 years. We see that they only wear out after 4 or 5 years. By continuously monitoring, we can collect data and proactively anticipate based on that data. Moreover, we can continue to develop and optimize. This way, we end up making an ever better and more sustainable product," John says.

Not me but us

."It also feels good, that you are doing something valuable for the environment. I think we should look less at 'what can I earn from it.' It's more about getting something out of it together, and that works doubly well. It's also a favor factor. We all just have to start thinking differently. Change the mindset above all."

Produce locally

"Actually, we are way too late. Turning a profit was reason for the big organizations to close everything in Europe and go to China. Then it became Bangladesh and now India. That shift is easy to see. Prosperity is rising in those countries as well. But if you try to produce locally, you don't have all those problems."

Any tips?

John: "Start looking operationally: what am I marketing and how. Ask yourself if you can reuse or design in such a way that you can eventually do it. It's important to examine from the design process: (1) can I reuse my product and (2) can I produce it locally. By building modularly, you can be very flexible. Modular and circular go hand in hand. Then, if you can also make it locally, it completes the circle."

Local production brings more advantages, by the way. For example, you can keep people working here, the logistics routes are shorter, you save energy and you name it. "What they can do on the other side of the world, we can do too. Better even! We have proven that by now. And I remain committed to showing that we 'just' do that here from Kerkrade."