Not many people will be familiar with lignin. Yet this substance, which gives plants their strength, is the most abundant organic material on earth after cellulose. It has many applications, provided you use the right techniques. The bio-refinery company Vertoro, a pioneer in green chemistry, is developing those techniques with help from the Just Transition Fund. The goal? A revolution in the oil industry. 'We see ourselves as a sustainable oil company.'

The miracle molecule lignin

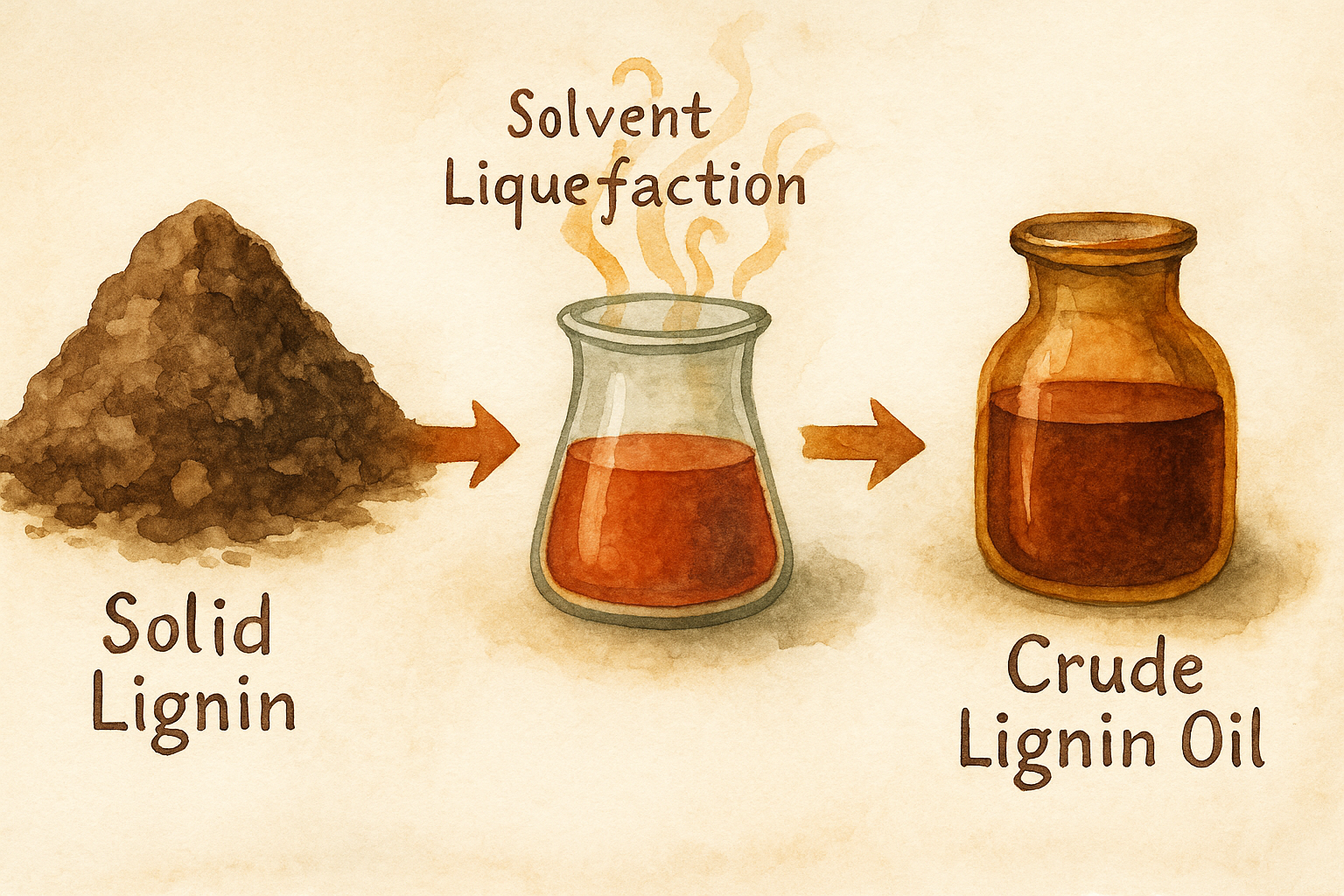

Very traditionally, lignin has been primarily a residual product, left over from making paper, for example. 'A shame, because it's actually a kind of miracle molecule,' says Michael Boot, co-founder of Vertoro. 'Because it has endless practical properties. Among other things, it can serve as a fuel, antioxidant, UV blocker, flame retardant or glue.' At Vertoro, they extract lignin from biomass that they get - also as a residual product - from agriculture and forestry. By boiling the lignin in alcohol to make it partially soluble, they turn it into lignin oil. "You can compare it to cooking coffee beans in water to make coffee," Michael said.

"We see ourselves as a sustainable oil company"

Fragrances and shipping

A major advantage of processing the lignin into oil is that it makes production so relatively easy and cheap to scale up. 'That means you get an excellent "platform molecule," says Michael. 'A basic building block that serves as a starting point for the production of all kinds of chemicals and materials. You can use it to make artificial fragrances and flavors, for example. Or employ it as a replacement for vitamin E.'

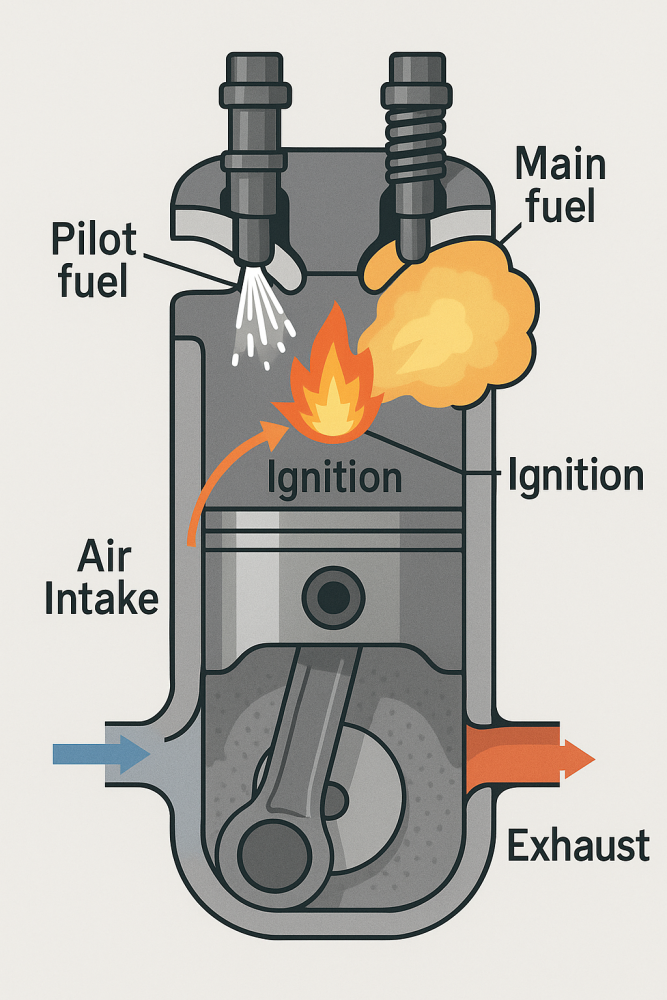

Lignin oil is also well-suited for use in shipping, which increasingly uses sustainable fuels such as bioethanol. Adding lignin to ethanol not only makes it cheaper but also easier to use. After all, the substance makes it easier for traditional marine engines to run on bioethanol because it improves ignition.

In short, plenty of opportunities. But to scale up production to industrial standards, Vertoro could make good use of the Just Transition Fund grant. Michael: "Through our scale-up, we can offer chemical companies more diverse applications for our lignin oil. That makes it more interesting for them to test with our oil. We are also using the money, among other things, to hire and retrain new staff, such as plant managers, operators and laboratory personnel.'

Complex but valuable

Some of the personnel working at Vertoro previously worked in the traditional chemical industry. 'So retraining was necessary,' says Michael. 'And because working with biomass is much more complex than working with oil, you have to pay a lot of attention to that. So that is one of the reasons that oil companies prefer to stay with gas and oil. We also give workshops three or four times a year in which we explain which aspects cause that complexity, and how to address it. For this we invite colleges, universities, as well as local SMEs and large companies. Everyone is welcome."

For Michael it is important that he contributes to the climate issue with Vertoro. 'That motivation is also necessary,' he says with a laugh. 'Because you don't start a startup to get rich. Indeed, you have to put in all your savings, and accept that your job regularly resembles a roller coaster. There is quite a lot of uncertainty, also because a different political wind is blowing at the moment and sustainability is getting a little less attention again. It is not easy to compete with the fossil industry. After all, that has been a well-oiled machine for 150 years. We can therefore use all the help we can get, such as from the JTF. This is how a sustainable alternative to fossil really comes closer.'