PP recycling b.v., an innovative recycling company from swalmen, has received a €20,000 grant from mit zuid-nederland for the repolycare project. With this grant, the company will investigate how toilet seat buckets for the healthcare sector can be produced locally from 100% recycled polypropylene.

From waste to healthcare product

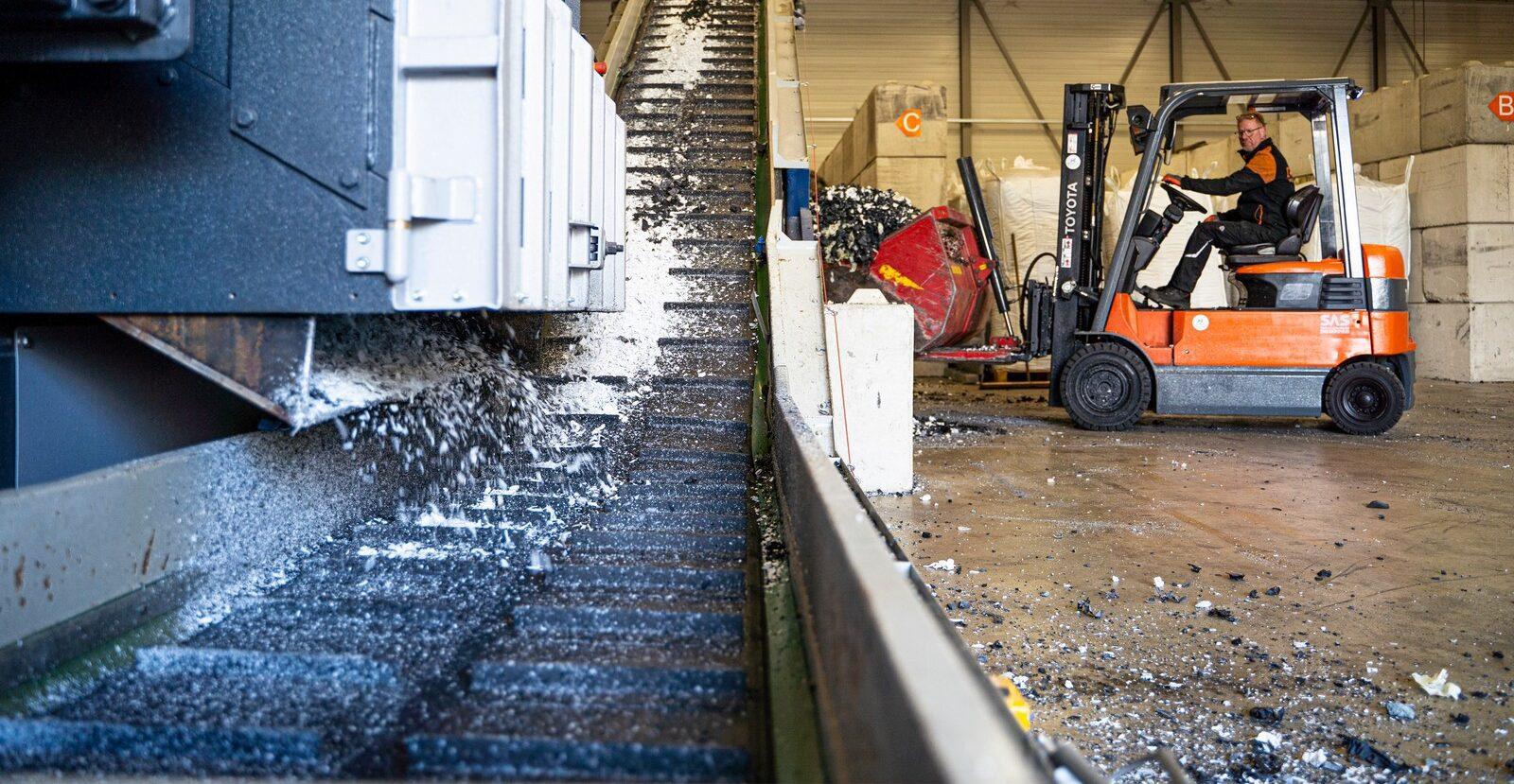

PP Recycling, founded in 2012, specializes in recycling plastics such as polypropylene (pp), polyethylene (pe) and polyolefins (po). The company transforms plastic waste from fruit crates, pallets and foils into high-quality raw materials for new applications. With the repolycare project, PP Recycling is now taking an important step toward circular production in the healthcare sector.

"We want to demonstrate that recycled materials are a viable alternative to virgin plastics in healthcare products," explains PP Recycling's project coordinator roul schroijen. "By producing locally from recycled materials, we not only reduce plastic waste, but also co2 emissions through shorter transport chains."

Collaboration with keyport

PP Recycling came into contact with Keyport through the Business Roadmaps program, in which the company developed a compact, maintainable and enthusiastic plan for the future. Even after completion of this program, PP Recyclin continued to work with Keyport project leader and coach of the Business Roadmaps program Jean-Paul Urlings. He now guides the company in its further professionalization and coordinates the implementation of the repolycare project.

"The Business Roadmaps program helped us sharpen our vision," Schroijen said. "Jean-Paul's guidance is valuable for the strategic and operational challenges we face with this innovative project."

Circular Innovation in Healthcare

The repolycare project, which runs from June 2025 to June 2026, focuses on the development of toilet seat buckets made from recycled polypropylene. These essential devices for people with mobility impairments are currently mostly imported from China and manufactured from virgin plastics.

"The healthcare sector has a great need for sustainable solutions," explains Schroijen. "With our circular toilet seat bucket, we offer a locally produced alternative that has the same functionality as conventional products, but with much less environmental impact."

The project includes three main phases: technical research into the feasibility of recycled materials, commercial research into market opportunities, and financial research into economic viability. PP Recycling is collaborating with healthcare partner Medicura and outside experts on 3D printing and material properties.

Future Outlook

On successful completion of the feasibility study, PP Recycling plans to develop five pilot models and a comprehensive market analysis. The company aims to make a significant contribution to the circular economy in the healthcare sector, with potential expansion into other European markets.

"This project fits perfectly with our mission to turn plastic waste into valuable products," Schroijen concludes. "We hope to set an example for other sectors and demonstrate that circular production can be both environmentally friendly and economically attractive."

The repolycare project contributes to MIT South's knowledge and innovation agendas in the areas of energy transition and sustainability, as well as health and care, and supports the transition to a circular economy in the southern Netherlands.

Learn more about what Keyport can do for you?

View the projects and/or contact one of the Keyport Business Developers.