An economy that damages the planet is a red economy; a green economy restores balance, but by sacrificing prosperity. A blue economy also creates that balance, but with the preservation of prosperity. Jeroen Rondeel started Blue Engineering with the ambition of contributing to such a blue world: a better world with all the comforts and without a Spartan lifestyle. It calls for products and processes that work radically differently from what we are used to. Cold plasma is such a completely different application. Rondeel explains more about it and invites farmers to present their problems to them.

Cold plasma has the potential to solve the most diverse odour and hygiene problems. The technique can be applied in healthcare, but also in the agricultural sector. Think of cleaning the udders of cows, which can be done perfectly with plasma-infused water. Breaking down the gases that cause odors in livestock buildings is a second option. But hygiene is also essential for gardeners: it ensures a significantly higher yield.

Blue Plasma

With those possibilities in mind, Blue Plasma Agro Solutions was born: a startup that further develops the technology developed by Blue Engineering for making and controlling Cold Atmospheric Plasma (KAP) in applications in food, agriculture and horticulture. With the help of a grant through LIOF LimburgAgrofood, Blue Plasma is now focusing on the cleaning and disinfection of surfaces, production machinery and air scrubbers in, for example, pig farms.

Cold plasma: the ideal thunderstorm

Rondeel explains the operation of cold plasma using the example of a thunderstorm. "Clouds have an electrical charge and when two clouds collide, lightning occurs. You see a flash: the electrical discharge. The same thing happens with cold plasma. Cold plasmas are ionized gases. When you take gas and put a substantial electric field on it, you see a flash of light. At that point the atoms split into ions and electrodes. You then get plasma, the fourth state of matter. Upon discharge, the electrons are knocked out of their orbit around the nucleus, breaking the cell walls of bacteria and viruses that are present. The causative agents of disease or odor do not survive this and what remains are simple structures, such as water and oxygen. Such an application is very interesting for the agro sector because it is very effective, uses no water and very little energy."

Add-on for more predictability

Cold plasma has existed for a while, but it is hardly used in the agricultural sector because it was still very unstable and that caused a lot of variation in the results. Rondeel: "We have now developed an add-on with which we can ensure stability. We expect to receive a patent for this add-on soon, the first patent for a technique that was developed at the Brightlands Campus Greenport Venlo. We are of course very proud of this, but above all we want to start testing the technique in practice soon. Every farmer and horticulturalist who has an odour or hygiene problem can contact us. Then we will see if and how we can help that entrepreneur."

Measuring odor

At the moment there is already a test rig on the campus where it analyzes gas from a pig barn. Rondeel: "Solving the problem starts with analyzing it: which elements or combinations of elements cause the smell? Is it the sulfur, is it the butyric acid? If we break down one, is the problem solved or should both be broken down? This sounds very logical, but measuring the exact composition and how the different substances interact has not been done before. Simply because it wasn't possible before. Thus, there is still much to investigate and endless applications imaginable for plasma. The technique is still quite new, but it is only a matter of time before plasma is used on a large scale. For example, UV lamps are still widely used for cleaning. That will become plasma, because it is easier to control and has a more active effect."

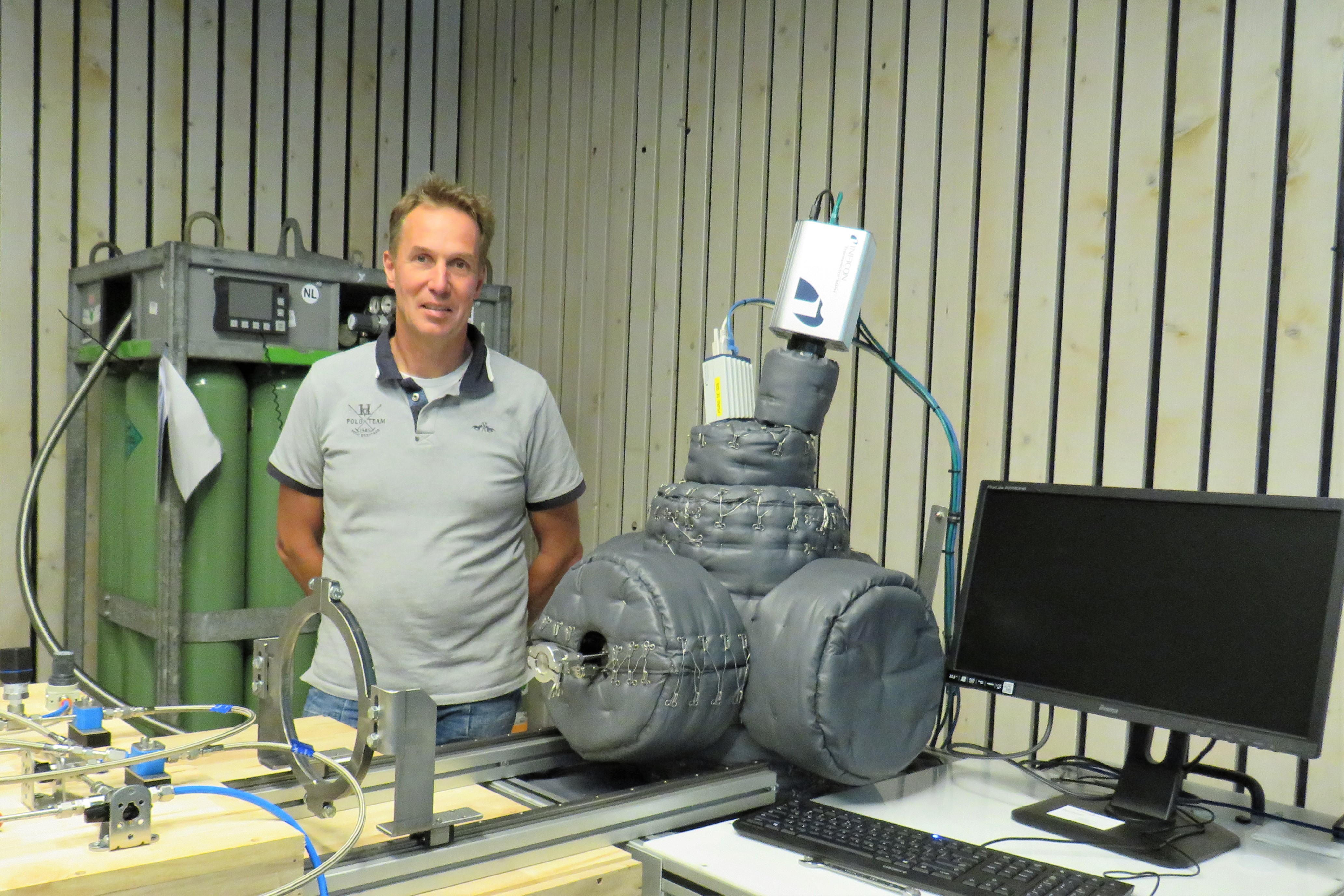

Jeroen Rondeel at the test stand to be able to analyze gases.

Peeling a problem

The process from technology to application is fascinating, Rondeel believes. "It often starts with a farmer who has some affinity with technology, but above all is a good specialist in his own field. Together with such an entrepreneur we then peel back the problem layer by layer. It was the same with the Wolky Tolky we developed. It started with a grower of Chinese coal who wanted to prevent burning from the inside. By asking a lot of questions and putting yourself in the entrepreneur's shoes, you discover that the core temperature is the most important indicator. And that is just a matter of placing a sensor. Combustion is then easily prevented by misting when the core temperature gets too high. In the case of cold plasma applications, the issues can be very diverse. As long as hygiene or odor play a role. We are now looking for farmers with hygiene problems so that we can analyze them together. In the end it always turns out that the solution is surprisingly simple."

High tech, very healthy

On October 10, Sustainability Day, during the Dutch Food Week, a meeting will take place under the heading 'Hightech meets Biomass'. There will also be a theme session about plasma to which interested parties are cordially invited. Rondeel: "How can you make sure that unhealthy substances do not spread through water, but can be extracted with the help of plasma? Professor Andreas Fath already swam across the Rhine in 2014 to investigate water quality and draw attention to the importance of healthy and clean water. It is a hot topic! With innovative filters and plasma technology, we can remove antibiotics, microplastics and drug residues from the water. We hope to get in touch soon with farmers who have become curious about the possibilities of plasma within their farms and want to take the plasma adventure with us."

If you would like to talk further about Blue Plasma, contact us >